2000: PORSCHE® TECHNOLOGY

.jpg)

Dr. Ing. h.c. F. Porsche AG is the first automobile manufacturer in the world to develop a ceramic composite brake disc with an involute cooling channel. The new 911 Turbo can be ordered with this on request from late autumn 2000. Retrofitting is also possible without any problems. The new brake, called the "Porsche Ceramic Composite Brake" (PCCB), is a significant advance in the field of vehicle brake technology and sets completely new standards. This applies to such crucial criteria as responsiveness, fading stability, weight and service life.

The ceramic composite brake disc is perforated and internally ventilated like the conventional metal brake disc. Its dimensions also differ only slightly from the round disc made of gray cast iron. But even when comparing the weights, it is clear that two different worlds are colliding here. The ceramic brake disc weighs over 50 percent less. This reduces the vehicle weight by up to 20 kilograms. This not only saves fuel, but also reduces the unsprung masses, which can further improve the responsiveness of the shock absorbers.

On the road, the new braking system proves to be absolutely exemplary. In conjunction with a completely new brake pad, the ceramic brake disc develops very high and, above all, constant friction values during deceleration. The operating temperature - a decisive factor for the braking distance with metal brake discs - only plays a minor role. Brake pads and ceramic brake discs do not tend to have lower friction values when they are cold or hot. The level always remains consistently high. This avoids unpleasant surprises for the driver when he has to brake from high speeds, for example. A brake that initially seems to have good grip and is not specifically designed for high speeds like Porsche brakes loses friction value at hot operating temperatures, which can only be compensated for by increasing pedal force.

But the new braking system from Porsche also shows clear advantages in emergency situations at low speeds. Emergency braking with PCCB requires neither high pedal force nor any technical aids that help build up maximum braking power in a fraction of a second. PCCB delivers maximum deceleration immediately and without strong pressure on the brake pedal. The new braking system also demonstrates excellent properties in terms of wet response. This is because the newly developed brake pad can absorb less water than conventional pads. The excellent braking performance in rainy weather is of course supported by the perforated brake disc.

The new ceramic brake disc can handle high loads, which can often occur with a sporty driving style, without complaint. The wear is extremely low compared to a metal brake disc. The ceramic brake disc owes this to its extreme surface hardness. Its life expectancy is correspondingly high. Extensive tests have shown that the disc lasts the life of the car and can reach a mileage of up to 300,000 kilometers. The corrosion resistance of the material used also guarantees the extremely long service life. The ceramic brake disc is completely resistant to road salt and liquid salts, which are used for automatic spray systems on motorway bridges, for example. The new brake pads also have a long service life. They have a mileage of around twice as long as conventional pads.

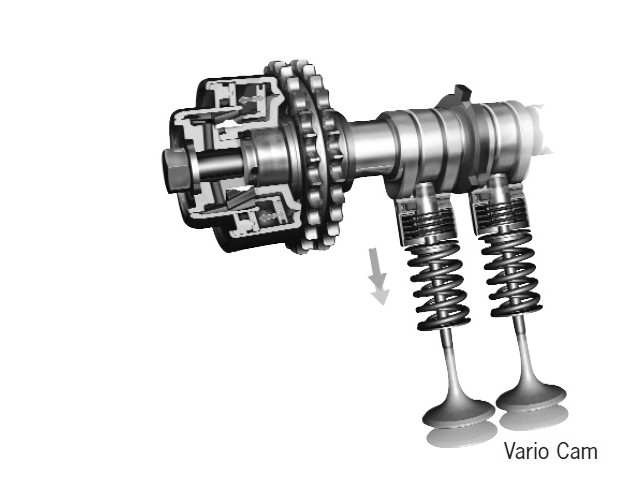

With "VarioCam Plus" in the new 911 Turbo, Porsche is offering two engine concepts in one for the first time. The system consists of four valves per cylinder, the axial camshaft adjusters and the switchable valve tappets. The two intake and exhaust valves are arranged in a V shape with a valve angle of 27.4 degrees. In order to keep the moving masses of the valve train as low as possible, the valve stem diameter is only six millimeters. In contrast to the 911 Carrera, double valve springs are used on the intake and exhaust valves to ensure that the valves close even when the forces caused by the exhaust back pressure are higher. The intake-side camshaft adjustment in the new 911 Turbo is expanded to include the intake-side valve lift switch. This allows power and torque to be optimized on the one hand and fuel consumption and exhaust emissions to be reduced and running smoothness to be improved on the other.

The valve lift adjustment system consists of switchable bucket tappets on the intake side of the engine, which are operated by an electro-hydraulic 3/2-way switching valve. Since two different cam shapes are mounted on the intake camshaft, the corresponding valve lift curves act on the engine by switching the respective cams. In detail, the bucket tappets consist of two nested tappets that can be locked together using a bolt. The inner tappet is in contact with the small cam, the outer tappet with the large cam. A hydraulic compensation element for the valve clearance is always integrated in the power flow of the tappet.

VarioCam Plus means two engine concepts in one. When idling, the engine is optimized by switching the valve lift to the small cam of three millimeters and adjusting the valve timing for low valve overlap. The small valve lift results in a reduction in friction, a significantly increased charge movement due to extremely shortened opening times and little exhaust gases from previous combustion in the combustion chamber. This results in consumption and emissions reductions of up to ten percent with significantly improved idling quality. At partial load, operation with internal exhaust gas recirculation is optimal for de-throttling the engine and thus reducing consumption.

For this purpose, the camshaft adjustment is set to a large overlap area with a small valve lift, i.e. a large proportion of time for sucking back exhaust gas from the exhaust. At full load, high torque and high peak power are achieved on the one hand by a low-loss gas exchange and on the other hand by an uncompromisingly designed cam contour with a maximum valve lift of ten millimeters and correspondingly adjusted opening and closing times of the valve lifts. VarioCam Plus also helps before a journey begins. For example, the cold start of the engine is significantly improved and during the warm-up phase of the engine, emissions can be reduced by adjusting the VarioCam Plus accordingly.

Both individual systems of the VarioCam Plus (camshaft adjustment and valve lift switching) are controlled by the Motronic control unit ME 7.8. The control unit has been specially designed for these requirements with high computing power. The input variables "engine speed", "accelerator pedal position", "engine oil and water temperature" and gear recognition are particularly required to control the VarioCam Plus. The desired torque or power is compared with the stored maps. The decision as to whether VarioCam Plus needs to react is made in milliseconds. If so, everything runs very quietly and silently despite huge changes to the engine design. There is no sign of this in the cockpit.

In addition to four-valve technology and water cooling, the new 911 Turbo owes its fuel consumption to the use of VarioCam Plus in particular, despite higher performance compared to the previous model. At 12.9 liters per 100 kilometers, its total consumption is around 18 percent lower according to the EC standard.

.jpg)

The Porsche development engineers have further refined the sporty Tiptronic S and created the option for manual short-term control during automatic operation. This means that a gear can be changed manually using the rocker switch on the steering wheel, even though the selector lever is still in the automatic position. The manual mode remains active for at least eight seconds if no further intervention is made. These eight seconds are extended in overrun mode, for example when driving downhill to achieve engine braking effect, or during lateral acceleration in curves if the driver has previously shifted down to be able to drive in a sporty manner. When driving in this mode, the "M" indicator lights up in the right-hand circular instrument and the gear engaged is displayed. At the same time, the kickdown function is retained so that downshifts can be made spontaneously. This causes the automatic transmission to jump back up to three gears - provided the driving speed and engine speed allow it.

In automatic mode, the Tiptronic S offers five programs with different maps stored in the control unit. They are each called up automatically in accordance with the driving style and route profile. The range of shift points extends from a particularly economical variant for a particularly quiet driving style (early upshifts, low engine speeds) to the highest driving dynamics (quick downshifts when accelerating, taking advantage of the engine's revving ability). The driver's foot on the accelerator is crucial here. Rapid accelerator pedal movements, for example on a winding road, as well as frequent, forceful acceleration result in the shift maps changing gradually, possibly up to the highly dynamic variant and vice versa. In addition to the five automatic maps, the Porsche Tiptronic S includes the following special features:

The 911 Carrera and Boxster models meet the EU3 limits that came into force on January 1, 2001. According to this exhaust gas law, 2.3 g/km for CO, 0.2 g/km for HC and 0.15 g/km for NOx are prescribed. In order to stay below these limits, the engine's starting and warm-up behavior has been improved, among other things. In addition, the catalytic converter reaches its operating temperature more quickly thanks to optimized ignition intervention. Like the 911 Turbo, which already meets the EU4 limits that came into force in 2005 under standard test conditions, the vehicles were equipped with an on-board diagnostic system (OBD) as standard. In the future, the Carrera and Boxster models will also work with four lambda sensors in the exhaust system, i.e. with one control and diagnostic sensor per cylinder row.

Porsche has long been going its own way when it comes to pollutant conversion and does not use a ceramic carrier for the three-way catalysts like most manufacturers, but rather a metal carrier. It is well suited to high temperature loads and, unlike ceramic, can dissipate the so-called "hot spots" well. A mixture of platinum, rhodium and palladium is now chosen as the coating, which has a higher temperature resistance and, compared to the previously used bimetal coating, starts at lower temperatures. At the same time, the precious metal content in the catalyst has been more than doubled.

Another highlight in the conversion of pollutants is the division of the metal carrier into two parts with the same catalyst volume. In between, the development engineers have installed an intermediate section in which the exhaust gas is swirled. The effect is astonishing: pollutants that previously passed through the catalyst without touching the convertible precious metal wall are further reduced. After the swirling section, they now meet the precious metal-coated wall in the second metal carrier section.

This catalyst technology in conjunction with the already known secondary air injection has paid off. All model variants of the 911 Carrera and the two Boxsters comply with all emissions regulations worldwide without any problems. Their emissions values even fall below the strict LEV (Low Emission Vehicle) standard and the limits applicable in Europe.

Since the last model year, the "POSIP" side airbag system has been standard on all Porsche sports cars. POSIP stands for "Porsche Side Impact Protection". These are new types of side airbags that offer the driver and front passenger more comprehensive protection than is usual with previous side airbags. What's special about them: the two airbags are designed in such a way that they can also develop their protective effect in an open convertible. Only Porsche offers side airbags with head protection suitable for convertibles.

The airbag modules housed in the door panel also differ from others in that they have a particularly large volume when inflated. With a capacity of 30 liters each, these large airbags offer the occupants not only the usual protection in the chest and pelvis area in the event of a side collision. The POSIP system protects the head in particular from contact with a side obstacle. POSIP ensures this superior level of safety through the above-average volume of the airbag in every position of the seat on its longitudinal adjustment.

The side airbags are each filled by a hybrid gas generator. The pyrotechnic component is minimal in this version; it is mainly used to open the valve, which allows a filling of the noble gases argon and helium to flow into the airbag from a pressure vessel. In the event of a collision, the two side airbags are triggered by a sensor on the sill under the door and the central triggering device on the center tunnel.

2000: PORSCHE® TECHNOLOGY

2004: PORSCHE® TECHNOLOGY

Porsche Press kit

Porsche Literature

Our Porsche Cars