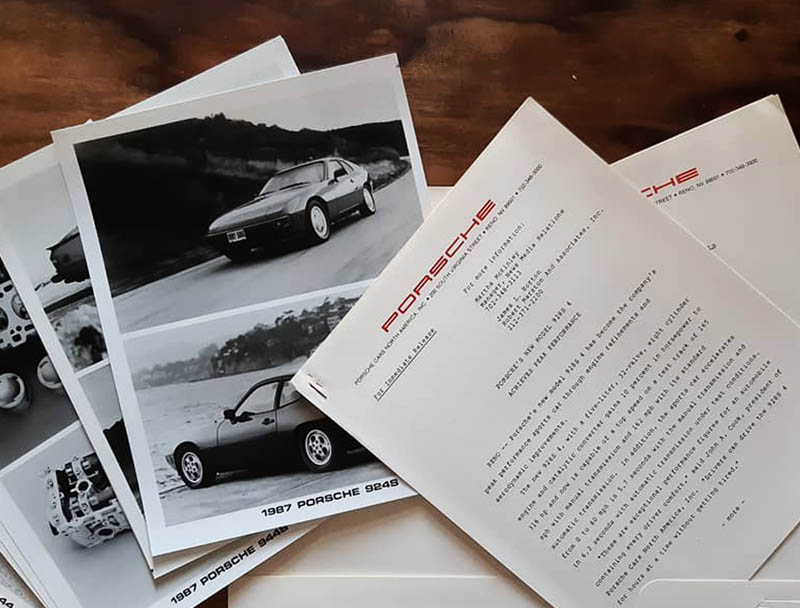

1993 Porsche 911 Turbo

The 911 Turbo 3.6 is the most powerful production car ever offered by Porsche for the U.S. market. For 1994, the Turbo 3.6 is powered by a larger engine, replacing the 3.3 liter engine which was used since 1978. The new engine is based on the 3.6 liter engine found in Porsche's normally-aspirated 911 models. The performance of the 1994 Porsche 911 Turbo 3.6 is the highest ever available in a roadgoing Porsche for American customers.

| 1994 | 1992 | |

| Cylinder bore | 100 mm | 97 mm |

| Stroke | 76,4 mm | 74.4 mm |

| Displacement | 3598 cc | 3299 cc |

| Compression ratio | 7.5:1 | 7.0:1 |

| Horsepower | 355 hp @ 5500 rpm | 315 hp @ 5750 rpm |

| Torque | 384 ft.-lbs @ 4200 rpm | 332 ft.-lbs. @ 4500 rpm |

| Redline | 6600 rpm | 6800 rpm |

| 0-60 mph | 4,7 sec. | 4.8 sec. |

| Top track Speed | 174 mph | 168 mph |

| Wheels | 8J & 10J x 18 | 7J & 9J x 17 |

| Tires | 225/40 & 265/35 ZR-18 | 205/50 & 255/40 ZR-17 |

Just as the 911 design is celebrating its 30th anniversary in 1994, fans of the 911 Turbo also have an anniversary to celebrate the original Porsche Turbo concept car was first shown to the public 20 years ago, at the Paris Auto Show in September, 1973. The production Turbo went on sale in late 1974.

Although other car manufacturers had tried turbocharging in the 1960s and early 1970s, in limited numbers and with only moderate success, it was Porsche that made exhaust-driven turbocharging a viable conceptfor production cars. The key to turbo reliability was a Porsche innovation, the exhaust wastegate which regulates turbo boost. Porsche's expertise turbocharging was gained on the world's race tracks, first with the al-conquering Type 917 which won the SCCA Can-Am racing series in 1972 and 1973. The 917 was followed by the 911 Carrera RSR Turbo, which ran in selected races during the 1974 season. Experience gained on the race track with the RSR Turbo was soon avallable on the street, when the production 911 Turbo became available.

In the 1990s, the Porsche 911 Turbo continues to race and win. With it, Porsche garnered consecutive IMSA Supercar Manufacturers Championships in 1991 and 1992; Hurley Haywood clinched the IMSA Supercar Drivers Championship in 1991. And the long string of successes continues, with a win in the GT Invitational Class at the 1993 Sebring 24 Hours.

The Turbo 3.6 is available only in coupe form, with Porsche's five-speed manual transmission. The bodywork remains virtually unchanged from the previous model; only the center section of the rear valance has been altered. New bright chrome "Turbo 3.6" script appears on the engine lid.

.jpg)

Although it is an ultra-high-performance car, the Porsche 911 Turbo 3.6 makes no sacrifices in comfort. The Turbo 3.6 is equipped with air conditioning, partial leather seats, a high-grade audio system, an on-board computer and an alarm system as standard equipment. A wide range of options and special equipment allows Turbo 3.6 owners to tailor their cars to their own special wishes.

The 1994 Turbo 3.6 is powered by a new 3.6 liter engine closely based on the normally aspirated engine used in the other 911 models. Crankshaft, connecting rods, and crankcase are shared with the non-turbo engine, but pistons, camshafts, and the K-Jetronic fuel injection system are specifically engineered for the Turbo 3.6. The 3.6 liter engine has a larger bore and stroke and higher compression ratio than the 3.3 liter it replaces, so both power output and maximum torque have been increased. This translates into improved drivability and brisk performance even before the turbo boost reaches its 0.7 bar (10 psi) maximum. As a side benefit, in norma driving, the 1994 Turbo 3.6 has fuel efficiency equa to its predecessors.

Porsche pioneered the "whale tail" spoiler for its 1975 Turbo. From the beginning, the rear spoiler was used not only to improve the car's high-speed stability and aerodynamics, but also to house the large air-to-air intercooler. This system, again based on Porsche's racing expertise, cools the intake air after it has been compressed by the turbocharger, resulting in better performance and fuel economy.

The larger, more powerful engine also necessitated a reinforced clutch. The transmission remains unchanged, with identical gear ratios and final drive. Porsche's limited slip differential is standard on the Turbo 3.6, with 20 percent lockup on acceleration and 100 percent while coasting.

The brakes of the Porsche 911 Turbo 3.6 are directly derived from the ventilated disc brakes developed for the legendary 917 race car of the early 1970s. The front rotors of the Turbo 3.6, 12.68 in. (322 mm) in diameter, feature an even greater swept area than those of its 3.3 liter predecessor. With a diameter of 11.77 in. (299 mm), the rear brake rotors are the same size as those used on the normally aspirated cars, and all four brake rotors of the Turbo 3.6 are cross-drilled for even better brake performance.

In brake systems, as in so many other components, Porsche's racing experience has led directly to major improvements for production cars - improvements customers can feel and use every day. Technology transfer from race track to street often results in race-proven systems finding their way directly to the assembly line. For example, the brake system used on the legendary Type 917 race cars in the early 1970s was applied to the 911 Turbo as of 1977.

The key to high-performance braking is heat management. The energy represented by the speed of the car must be converted to heat and transferred to the surrounding air as quickly as possible. Managing this heat transfer requires careful design of the mechanical parts of the brake system, as well as the bodywork and ducting of the car.

Porsche design parameters for improved brake system performance include the following:

Porsche's brake discs employ spiral-shaped internal cooling ribs, with additional half-ribs to radiate heat away from the rubbing surfaces. Ilt takes more to duct cooling air to the brakes than simply cutting the biggest possible holes in the bodywork. Too much cooling air flow will increase drag and front-end lift. Too litte air flow results in overheating and altered brake bias. Porsche has found the best compromise in underbody ducting in the nose, a flexible spoiler attached to the lower suspension arms, and a deflector plate attached to the suspension to direct air through the brake splash shield. Wheel design is also a vital element of the brake cooling system. The openings between the spokes must be designed to extract hot air from under the fenders.

Porsche conducts extensive laboratory and road tests to optimize brake designs. The final testis how the brake system performs on the road. Porsche tests on famous race tracks such as the Nürburgring and Hockenheimring , and under real-world conditions such as the steep mountain roads on Mont Ventoux in southern France.

The net result of Porsche's quest for the ultimate in braking performance is that every Porsche production car is capable of extended duty on race tracks without any special modifications to the brake system. In view of such rigorous demands , it comes as no surprise that Porsche brakes provide the utmost in stopping ablity under everyday driving conditions.

.jpg)

The race-proven suspension of the Turbo 3.6 is carried forward rom the last 3.3 liter model. The front suspension uses MacPherson struts with gas-filled shock absorbers, forged aluminum alloy lower control arms, and a 0.83 inch (21 mm) stabilizer bar, Rear suspension features gas-flled shocks, toe-correcting semi-trailing arms, a 0.87 inch (22 mm) stabilizer bar and progressively wound coil springs which give a soft ride with small suspension movements but stiffen under increasing suspension compression.

Increased power and performance demand larger wheels and tires. Of all Porsches, the Turbo 3.6 is unique in carrying 18-inch tires as standard equipment, on 8-inch front and 10- inch rear wheels. The wheels are true three-piece pressure-cast alloys, with a center section bolted to the outer rims The extremely low profile Z-rated tires, 225/40 at the front and 265/35 at the rear, provide the necessary grip to put the engine's power on the road.

The Turbo 3.6 is equipped with force-sensitive hydraulically assisted rack and pinion steering. This system isolates road irregularities and bumps, yet permits the driver to sense cornering forces through the steering wheel and interact with the car.

At Porsche, safety begins with a car's driving characteristics. The dynamic behavior of Porsche sports cars is the result of advanced testing and experimentation, as well as experience on the race track. The results are uncompromising design of suspension, steering, and brakes. Safety considerations are also reflected in the comfort, excellent visibility, and ergonomically correct design of Porsche sports cars.

Safety is not a new concept at Porsche. As early as 1952, all Porsche cars were fitted with laminated safety glass windshields. In 1956, Porsche offered seat belts as an option on the 356. A 1959 race car, the Type 718, pioneered the articulated steering column which today is used on all Porsche models. In 1961, Porsche offered a shoulder belt as an option, and in the following year made three-point belts available. Racing experience led to the introduction of plastic fuel tanks,first used in the racing-only 911 R of 1967. Plastic tanks are not only impact and fire resistant, but are also impervious to corrosion. Since 1973, every Porsche 911 has been equipped with door reinforcements for increased protection in side impacts. In 1990, Porsche was the first auto manufacturer to equip all of its products with anti-lock brakes. Also in 1990, Porsche was the first manufacturer, domestic or import, to equip every car sold in the United States with driver as well as front passenger airbags as standard equipment.

Airbags and safety belts represent just one level of protection for the occupants, however. The car's structure is also designed for safety, with a rigid cage to surround the occupants and deformable crush zones to absorb impacts. Porsche was the first manufacturer to build car bodies using sheet steel galvanized on both sides. This not only preserves the appearance of the car and the owner's investment, but also maintains the built-in crash- worthiness of the car. Porsche is one of only two manufacturers who feels so strongly about its corrosion protection measures that it provides a full ten-year limited warranty against rust perforation. Even the paint carries a three-year limited warranty.

Porsche is not only pioneer in high technology and high performance, but an industry leader in environmental responsibility. This begins with building cars to last. Of all the Porsches built since 1948, it is estimated that 80 percent are still in service. Part of that longevity comes from the fully galvanized bodywork of the Porsche 911. Its durability has been a factor in maintaining Porsche's traditionally high resale values and unparalleled owner loyalty.

During development of the 1995 91 1 Carrera, the goal of recyclability of a high proportion of materials used in producing the car was given priority - and achieved. If and when a Porsche reaches the end of its useful life, labeling of various plastic components willmake it easier to reprocess parts, and will help to put plastics back into consumer products, not in landiflls. Lightweight metals, such as aluminum and magnesium, as well as steel, are easily recycled.

Despite their high performance, Porsche cars are among the cleanest on the road. Highly effective three-way catalytic converters, oxygen sensors, and engine management systems have long been partof the Porsche pedigree. Al Porsche models are equipped with systems that fulfill the most stringent exhaust standards worldwide.

Growing concern about the possible effects of chlorofluorocarbons, including the CFC-12 refrigerants used in automotive air conditioning systems, on the earth's ozone layer led Porsche to introduce a CFC-free refrigerant, HFC-134a, beginning with its 1993 models. The higher cost of HFC-134a, and its higher salvage value, also provide a monetary recycling incentive for repair shops.

Porsche owners who would like to further personalize their cars can take advantage of Porsche's special options program. Porsche offers a wide range of special order items to make each car uniquely individual. These include paint to match any sample color and leather to dupli licate any sample shade. Virtually every interior item may be ordered with factory-applied leather trim.

Every Porsche may be ordered through participating U.S.dealers for European delivery This program offers an unforgettable driving experience, enabling the buyer to sample the high-speed motorways and scenic, winding secondary roads which gave birth to the Porsche legend.

Thanks to decades of experience building solid, urable high-performance cars, Porsche's warranty coverage is among the broadest of any sports car manufacturer. Each Porsche is covered by a two-year new vehicle limited warranty with unlimited mileage, which includes the Porsche roadside assistance program. The fully galvanized body and 26-step paint and anti-corrosion process enable Porsche to warrant each car for ten years and unlimited mileage against rust perforation, protection unmatched by any other sports car manufacturer. In addition, the paintwork carries a three-year limited warranty.

In addition to the extensive warranty coverage of Porsche cars, Porsche also warrants parts and accessories for two years and unlimited mileage. For parts and accessories installed by authorized Porsche dealers, labor costs are also covered.

Porsche Credit Corporation offers attractive leasing, financing and balloon payment plans for new and used Porsche sports cars. The "Porsche Preferred Lease" program is available for new Porsche sports cars and for 1991-1994 pre-owned cars. The lease term can be as long as 60 months. Finance terms of up to 84 months are available. The "Porsche Options" program combines the economies of leasing with the benefits of ownership for new Porsches as well as 1990-1994 pre-owned Porsches. (Certain programs may not be available in all 50 states.)

These financial options allow more American drivers to enjoy the thrill of the Porsche experience, an experience which draws on Porsche's legendary heritage as the maker of both the world's finest performance automobiles and some of the most innovative and successful cars in the history of automobile racing.

1993 Porsche 911 Turbo

.jpg)

1997 Porsche 911 Turbo

Porsche Press kit

Porsche Literature

Our Porsche Cars