2001 Technology

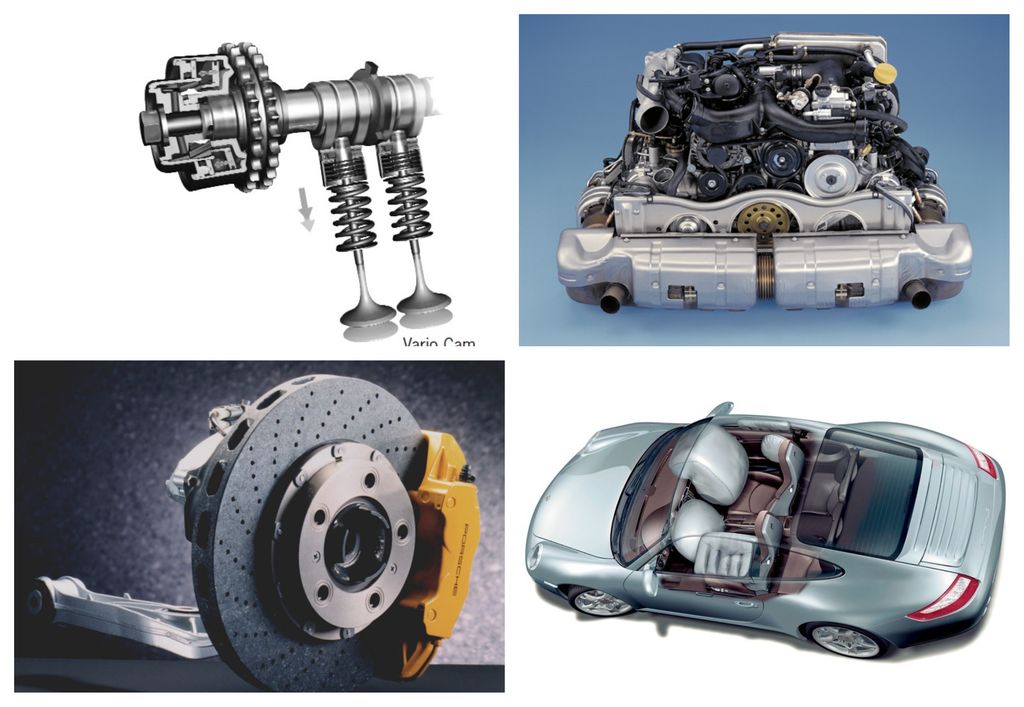

Dr. Ing. h.c. F. Porsche AG is the first car maker in the world to develop the ceramic composite brake disc with involvent cooling ducts featured as standard on the 911 GT2. Called “Porsche Ceramic Composite Brake” (PCCB), this new brake technology is a huge step forward, setting entirely new standards in the world of motoring, particularly when it comes to crucial criteria such as brake response, resistance to fading, weight, and service life.

Like Porsche's conventional metal brake discs, the ceramic composite brake discs are crossdrilled and vented from inside. In their dimensions they also differ only slightly from greycast iron discs. But comparing their weight, you will see right away that we are looking at two different worlds, with ceramic brake discs more than 50 per cent lighter. This reduces the weight of the car by exactly 16.6 kg. And apart from saving fuel, this also means a reduction in unsprung masses with a further improvement of shock absorber response and behaviour.

On the road the new brake system ensures absolutely exemplary results. In conjunction with the all-new brake pads, the ceramic brake disc ensures very high and, in particular, consistent frictional values throughout the entire deceleration process. Brake temperature – a factor crucial to stopping distances with metal brake discs – is now only a minor factor, since both the brake pad and ceramic brake disc retain their high level of friction regardless of whether they are hot or cold. This spares the driver unpleasant surprises whenever having to apply the brakes, say, from a high speed. Brakes which initially appear to offer good grip but are not designed especially for high speeds like the brakes on a Porsche, lose their frictional coefficient in hot temperatures, requiring the driver to press down the brake pedal even harder.

Porsche's new brake system also offers obvious advantages in emergencies at low speeds: In such a case emergency application of the brakes with PCCB technology does not require substantial pedal forces or any technical assistance serving to build up maximum brake forces within fractions of a second. Instead, the Porsche Ceramic Composite Brake ensures maximum deceleration from the start without requiring any particular pressure on the brake pedal. And the new brake system is just as superior in its response under wet conditions, since the new brake pads cannot absorb as much water as conventional pads. The final point, of course, is that the cross-drilled brake discs help to optimise the response of the brakes also in wet weather.

The new ceramic brake disc does not have the slightest problem with high loads occurring particularly under sporting, dynamic driving conditions. Compared with metal brake discs, surface abrasion is very low indeed thanks to the extremely hard surface of the ceramic disc. Working life, in turn, is increased accordingly. A further factor contributing to this extremely long working life is the total avoidance of corrosion: The ceramic brake disc is absolutely immune to salt scattered or sprayed on to the roads, for example by automatic spraying systems on motorway bridges. The new brake pads have a correspondingly long working life and last for about twice the mileage of conventional ones.

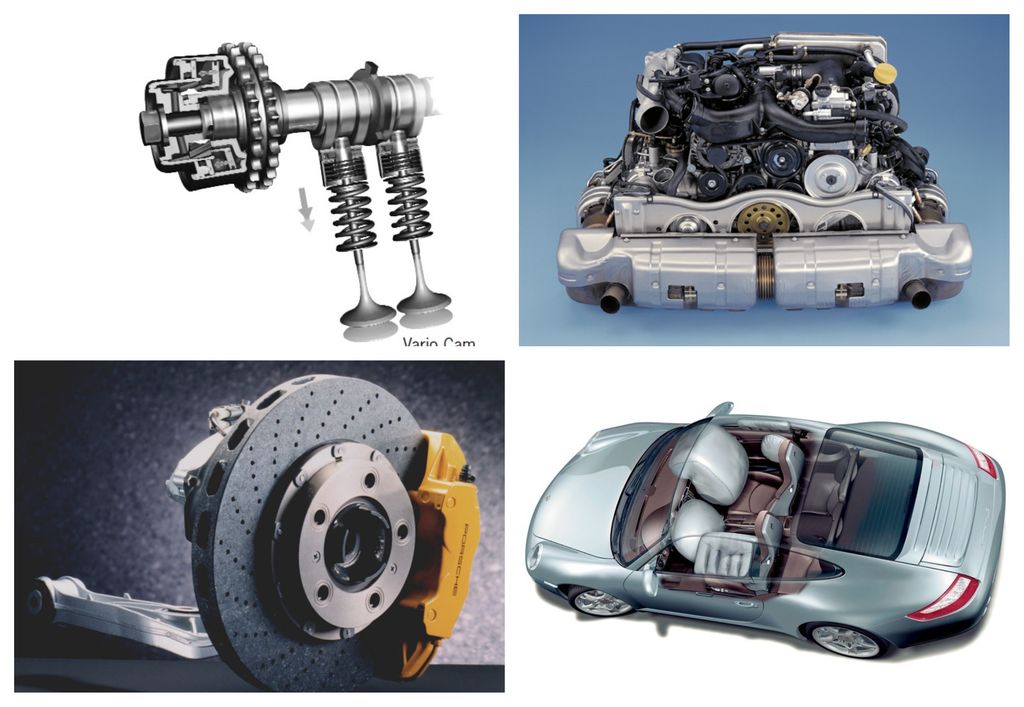

Porsche now offers VarioCam Plus on all models throughout the range. Camshaft adjustment on the intake side (VarioCam) is supplemented in this case by valve lift control also on the intake side (Plus). Featured for the first time on the 911 Turbo, this new system is able to optimise output and performance, on the one hand, while at the same time reducing fuel consumption and exhaust emissions, and improving running smoothness and refinement, on the other.

The valve adjustment system is made up of switching cup tappets on the intake side of the engine operated by an electrohydraulic 3/2-way switching valve. With two different cam contours on the intake camshaft, the engine always runs on the appropriate lift curve, with the cams switching from one to the other. To be specific, the cup tappets are made up of two interacting tappet elements locked one against the other with the help of a bolt. This creates a direct link, first, between the inner tappet and the small cam, and, second, between the outer tappet and the large cam. A hydraulic compensation unit for valve play is integrated in all cases in the tappet’s force flow line.

For all practical purposes VarioCam Plus means two engine concepts in one. As long as the engine is idling, valve lift is controlled by the small cams to a maximum limit of 3.6 millimetres and valve timing is optimised to keep any valve overlap on the engine to a minimum. The small valve lift serves to reduce friction, significantly increases the charge motion thanks to the very short opening times, and reduces emissions from any previous combustion within the combustion chambers. A further advantage is the considerable reduction in fuel consumption and emissions by up to 10 per cent, together with a much higher standard of idling quality. Under part load, in turn, the engine should preferably run with internal recirculation of exhaust gases in order to minimise any throttle effect and to reduce fuel consumption accordingly. To achieve this goal, valve lift is shifted to a large overlap area, that is a long period for drawing in exhaust gases. Under full load, finally, superior torque and output are ensured by a highly efficient gas charge cycle with minimum losses, on the one hand, and an uncompromising cam contour, on the other, with 11 millimetres maximum valve lift and suitably adjusted opening and closing times during the valve cycle. VarioCam Plus also helps before you set out, for example, by considerably improving the engine’s starting characteristics when cool and by reducing emissions through the suitable adjustment of VarioCam Plus while the engine is warming up.

Both of the two VarioCam Plus systems (camshaft adjustment and valve lift control) are masterminded by Motronic ME7.8 designed especially for these particular requirements and offering a high standard of operating and computing capacity. This is indeed important, since the factors required for controlling VarioCam Plus are, in particular, engine speed, gas pedal position, engine oil and coolant temperature, as well as recognition of the gear currently in mesh. The driver’s commands in terms of engine power or torque are compared with control maps within the system, the Motronic control unit then deciding within milliseconds how VarioCam Plus should respond.

.jpg)

A major feature of Tiptronic S is the option to briefly intervene in the transmission while in the automatic mode. This means that the driver, moving a toggle switch on the steering wheel, can shift gears manually even though the selector lever remains in automatic. The manual mode is thus activated for at least 8 seconds, this minimum period being extended when the car is in overrun – for example on a downhill gradient – in order to capitalise on the braking effect of the engine, or under lateral acceleration in bends whenever the driver shifts down in advance for a particularly sporting style of motoring. As long as this mode is active, the letter “M” comes on in the right-hand instrument dial and the gear currently in mesh is displayed. At the same time the transmission retains its kickdown function enabling the driver to shift down spontaneously whenever required: Road and engine speed allowing, the automatic transmission will shift down by a maximum of three gears as soon as the driver steps hard and quickly on to the gas pedal.

In the automatic mode Tiptronic S offers various programs with different control maps readily available in the control unit and activated automatically as an infinite function of the driver's style of motoring on the route he is taking. The range of shift points extends from a particularly economic variant activated whenever the driver prefers a calmer and more reserved style of motoring (with the gears shifting up at an earlier point and engine speeds being reduced accordingly) all the way to a very dynamic, active mode (with the gears remaining in mesh for as long as possible when accelerating, using the engine's free-revving driving characteristics).

The crucial factor in all cases is the driver's foot on the accelerator: Moving the gas pedal quickly and dynamically, for example on a winding road, and accelerating frequently with full power, the gearshift points will change accordingly, switching if necessary to the most dynamic variant and vice versa. Over and above its ability to recognise the driver's style of motoring, Porsche Tiptronic S also features the following particular highlights:

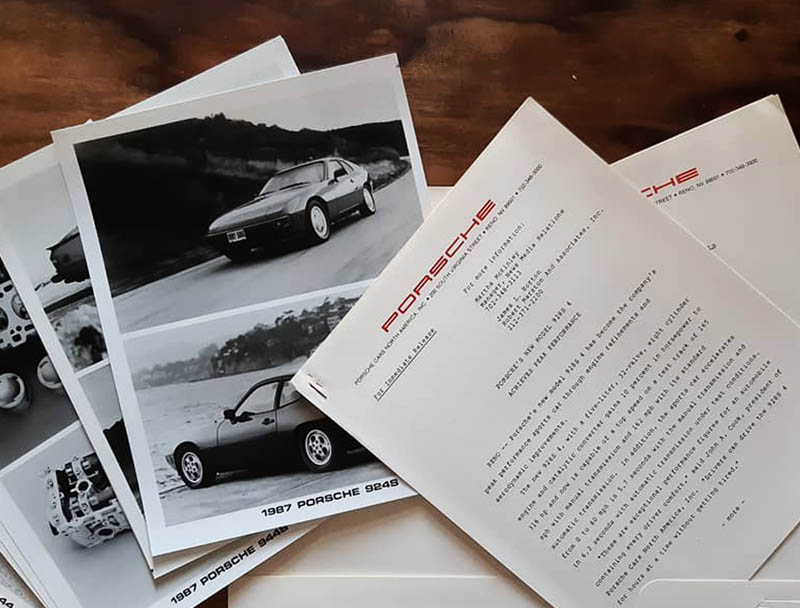

The POSIP sidebag system is standard on all Porsche sports cars. POSIP stands for Porsche Side Impact Protection and comprises sidebags offering the driver and front passenger a broader scope of protection than conventional side airbags are able to provide. Another special feature of POSIP is that the two airbags are able to ensure the same superior protection also in an open convertible.

Housed in the door panel, the airbag modules differ from conventional units also through their large volume and the geometry of the airbags. In a collision from the side, this ensures not only the usual protection from chest to head level – rather, protection of the driver's and front passenger's head from hitting an obstacle at the side is particularly effective. This superior standard of all-round safety ensured by the POSIP system is maintained in all cases regardless of the fore-and-aft position of the seat.

The side airbags are inflated when required by a hybrid gas generator. Accordingly, the pyrotechnical system is restricted to an absolute minimum in this case, serving primarily to open the valve in a collision allowing the two precious gases argon and helium to flow out of a pressure vessel into the gas-tight airbags actuated when required by a sensor on the sill beneath the door and the central actuator on the instrument panel.

2001 Technology

2004 Technology

Porsche Press kit

Porsche Literature

Our Porsche Cars