Porsche Press kit 1993

.jpg)

The Avant RS2, a cooperative development of Audi ard Porsche, has its world premiere at the IAA in September, 1993, in Frankfurt. The Avant RS2 is a self. sufficient model which could only be realized with these specifications and sty. ling through cooperation of the two independent automobile manufacturers.

This synergy in the technical realm is one side of the joint effort. The other is the business side: economic results of this cooperation will be divided equally between the two companies.

The high technical level of S2 models from Audi, plus know-how from Porsche as developer of exclusive sports cars and as specialist in the production of small series, permitted realization of this RS2 project within an exceptionally tight time frame

Basis of this Avant RS2 development is the Audi Avant S2. With its body shape and performance it introduced the trend to compact, sporting station wagons.

The high-performance RS2 wagon stands out for its individual styling with body elements such as bumpers and outside mirrors in Porsche design, its quattro chassis with Porsche light-alloy wheels and brakes, easily recognized at a glance by the red brake saddles with Porsche script, extravagant sporting fittings and notably high performance capability.

The 2.2 liter, 20 valve, five-cylinder turbo engine comes from the Audi Avant S2 where it produces 169 kW (230 HP). For the Avant RS2 Porsche raised the output of this power plant to 232 kW (315 HP). *

This gives a top speed of 262 km/h* for the Avant RS 2 and acceleration from 0 to 100 km/h in 5.8 seconds. * The wide torque band with a peak of 400 newtons,* provides powerful propulsion in all driving situations.

Standard quattro drive determines the sporting handling and ensures that the high performance potential can be transferred to the road in sovereign manner. The sporting chassis is attuned to this performance, while Porsche bra kes provide matching high deceleration.

This Avant RS2 is a high-performance sports wagon of explicit exclusiveness Production will begin at the Porsche factory in Zuffenhausen at the beginning of 1994. A total of 2000 units are planned for 1994 and 1995.

Sales begin in September. The first Avant RS2 will be delivered in the spring of 1994, at a price of 98,900 marks.

The special nature of this RS2 project as well as the small series presented new challenges to development and production engineers of both automobile manufacturers.

Porsche is developing and testing the specific Avant RS2 package including, among other things, adaptation of the quattro sports chassis and will carry out final assembly at its Zuffenhausen plant.

Production of the Avant RS2 follows an altered assembly process, differing from mass-production methods. Audi will deliver painted Avant bodies to Zuffenhausen as well as assembly components unchanged from the S2, such as dashboard, rear seat unit, quattro chassis and most accessories.

Porsche complements these deliveries with its own parts as well as those developed specifically for the RS2. Porsche also handles a range of purchased parts, such as the instrument combination and most interior fittings, inclu- ding Recaro sport seats and upholstery in RS2 design.

High potential output of the five-cylinder, turbocharged engine determines the overall impression of the Avant RS2. In order to direct sufficient fresh air to the intercooler and front-wheel brakes, the nose has been properly shaped and fitted with large intake openings. Typical Porsche styling elements were intentionally applied here. Smal auxiliary lights in the nose as well as aluminum wheels and outside mirrors from Porsche underline this impression. Red, blue and silver RS2 emblems and Porsche script deco- rate nose and tail of this high-performance wagon.

The lowered sports chassis is sportingly stiff. When it comes to engine output and equipment this Avant RS2 is truly an especially powerful vehicle with its extra-wide tires in the dimension 245/40 ZR 17 on 7 J x 17 inch light-alloy wheels.

The robust Audi five-cylinder engine of 2226 cc displays exceptional power reserves: in the Avant RS2 this supercharged, four- valve, turbo engine with interc ooler and electronic boost pressure control now produces a standard 232 kW (315 HP) at 6500 RPM* and exceptional torque of 400 newtons over a wide revolution range from 2800 RPM to 4900 RPM.*

This performance increase was achieved by modifications to the intake mani- fold and exhaust system as well as by using an optimized intercooler and larger turbocharger. In addition, engine management is undergoing fine tuning and camshafts are being reworked to adjust valve timing.

A power plant of unusual elasticity and outstanding pulling power is available due to high torque, spread over a wide rev range.

The turbo engine with compression of 9.0* is laid out for Super Plus (98 RON). Thanks to cylinder-selective knock control via two sensors, Euro Super (95 RON) can also be used with a minor loss of power. Consumption values to DIN norm 70 030 are 14.5 l/100 lm for the city cycle, 8.2 l/100 lm at a constant 90 km/h km and 9.7 l/100 lm at a constant 120 km/h. *

Excellent performance can be achieved in the Avant RS2 with its sportingly- staged six-speed gearbox: acceleration from 0 to 100 km/h in 5.8 seconds, top speed of 262 km/h.*

The sporting appearance of the Avant RS2 is continued in the passenger compartment. This presents itself as newly- developed, extravagant interior design which will be exclusive to the Avant RS2. This is underlined by three colors matched to external paint: color-intensive RS blue or red as well as a more neutral gray.

Driver and front passenger will sit in Recaro sports seats with electric height and back-rest adjustment.

An RS2 emblem and Porsche script decorate the Audi sports steering wheel. Steering wheel spokes are covered in Alcantara in the chosen interior color or, optionally, in black leather.

The sports steering wheel is delivered in conjunction with procon-ten. An alternative at no extra cost is the standard steering wheel for all '94 Audi models with driver air bag.

All faces of the analog instruments are white, the four main nstruments are trimmed with aluminum rings. Panels with carbon fiber inserts on the dash- board and door panels further underline the sporting look of this interior.

The customer can choose from five exterior colors: RS blue with pearl effect and laser red, Ragusa metallic or volcano black-pearl effect, as well as Porsche's polar silver.

Standard equipment includes, among other things, electric window lifts front and rear, headlight cleaning unit and naturally the fully-galvanized body.

* preliminary data

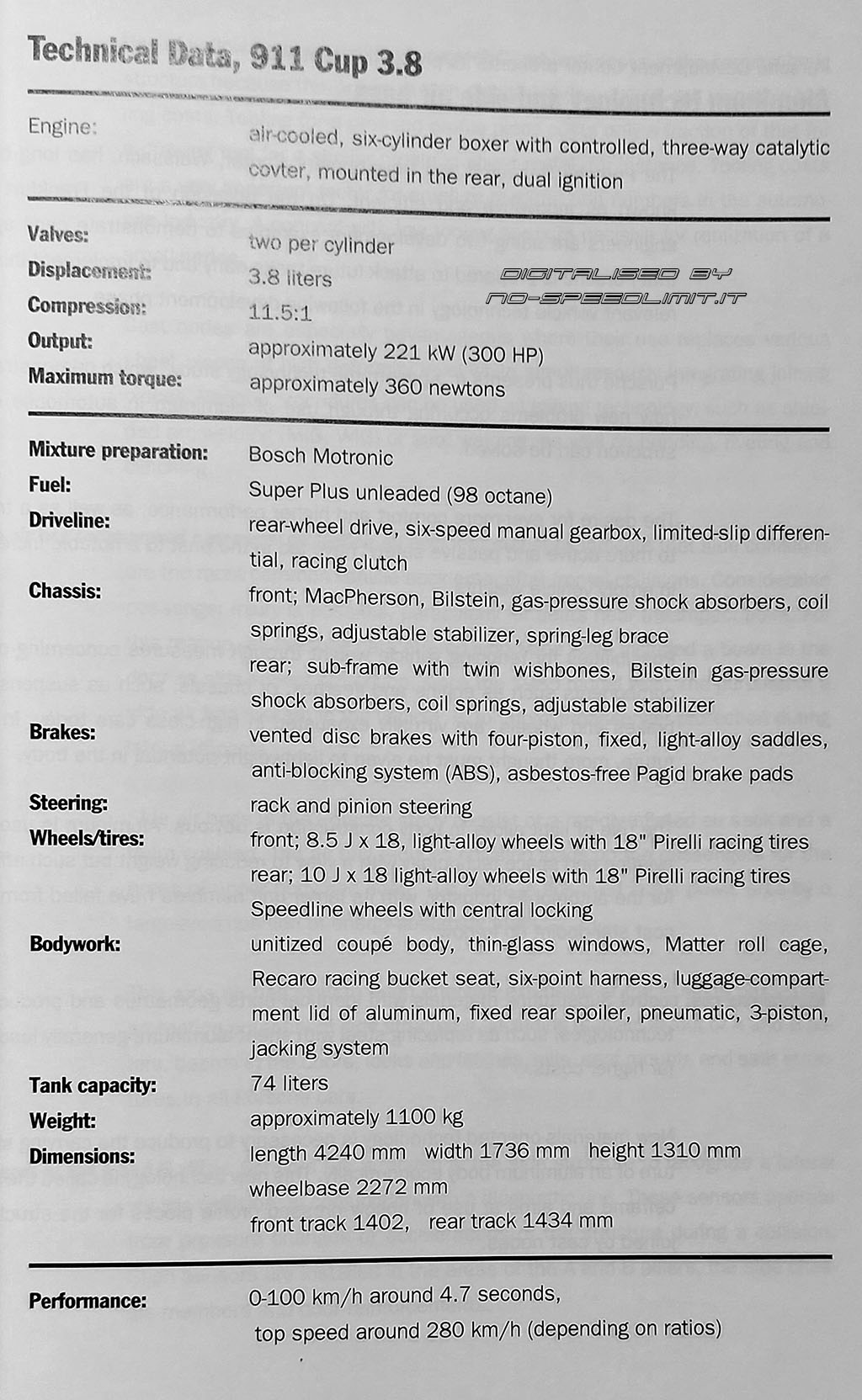

Porsche will continue its successful Supercup during the 1994 motor racing season. This racing series was launched in the spring of 1993. A field of specially-modified type 911 Carrera racing cars contests its own events on the programs of international Formula 1 races and those of the German Touring Car Championship.

The new Porsche 911 Carrera will form the basis for Supercup cars in the coming season. These Cup Carreras differ from the road version through a range of changes, such as enlarging displacement to 3.8 liters, increasing output to around 300 HP and tuning the chassis for racing use.

Cup Carreras will be built by the Porsche race sport department. Differences to the basic version of the 911 Carrera are listed in the technical data.

The Porsche Research and Development Center, Weissach has long been known as innovative and efficient. On the occasion of the Frankfurt IAA engineers are using two development examples to demnonstrate once again that Porsche is prepared to attack future tasks early and to implement this as relevant vehicle technology in the following development phase. Porsche thus presents a "spaceframe technology study" which demonstrates how new problems occurring through use of aluminum in automobile construction can be solved.

The desire for ever-more comfort and higher performance, as well as a trend to more active and passive safety, have led in the past to a notable increase in empty vehicle weights.

Possibilities for reducing vehicle weight through measures concerning drive components such as engine and gearbox, or chassis, such as suspension, brakes and wheels, are virtually exhausted in high-class cars today. In the future, more thought must be given to lightweight potential in the body.

The use of light alloys in body construction is obvious. Aluminum is used in aviation and space technology with a view to reducing weight but such efforts for the automobile industry, with its larger unit numbers have failed from the cost standpoint up to now.

Substituting materials with identical parts geometries and production technologies, such as replacing steel with sheet aluminum, generally leads to far higher costs.

New materials-oriented technology is necessary to produce the carrying struc- ture of an aluminum body economically. This new technology is called the spa ceframe and aims at use of hollow pressed profile pieces for the structure, joined by cast nodes.

Use of hollow pressed profiles is especially advantageous in the carrying body structure because this achieves high rigidity with low weight and favorable too ling costs. Tooling for a pressed profile piece costs only a fraction of that for a drawing tool for a similar profile in sheet metal, for instance. Tooling costs are a very important factor for small to medium unit numbers in the automo bile industry. A concept with low tooling costs is decisive for realization of a small series.

Cast nodes are especially advantageous where their use replaces various sheet pieces of high deformity level while simultaneously integrating joining pieces. Various procedures can be used as joining technology, such as shielded arc welding (MIG, WIG) or spot welding, as well as bonding, riveting and clinching.

All accident statistics indicate that side collisions are the most common vehicle accidents, after frontal collisions. Considerable passenger injury is possible, particularly for seats near the impact point. For this reason, all Porsche cars offered worldwide have included a beam in the door as side-impact protection, since the 1985 model year. The purpose of a side air bag system in the vehicle is to improve passenger protection during lateral impacts.

Side air bags in the Porsche study consist of a rapidly-inflated air sack and a foam cushion. The air bag reduces collision loads on the passengers for the areas of upper body and head. The same is achieved in the pelvis area by a large-area cushion of energy-absorbing foam.

This side air bag system is an effective extension of the existing passenger protection potential of side structures, including relevant layout of A and B pillars, beams in the doors, locks and latches, sills, seat mounts and seat struc- tures in all Porsche cars.

Sensors are arranged in the side structure to recognize a lateral vehicle collision, in conjunction with a diagnostic unit. These sensors operate from pressure changes or accelerations of the structure during a collision Such sensors are installed in the areas of the A and B pillars, the side chassis members and door reinforcements.

Integrated evaluation logic with self-diagnosis evaluates signals from the various sensors, Within a few milliseconds it analyzes whether a side collision has occurred and whether the side air bag system must be activated.

The folded air bag lies under the inner door panel. in normal driving passen- gers enjoy full freedom of movement in the upper-body area while optimum passenger protection is available through the side air bag system. Inflated the air bag has a volume of around 25 liters. The air bag side facing the passengers consists of gastight material while the side of the air bag opposite the passenger is laid out te be permeable to gas. Stiffness of the air bag is controlled by the gas permeability of the sack material, without gas from the air bag contacting passengers.

A pyrotechnic gas generator unfolds and inflates the bag. High demands are placed on this gas generator. It must deliver roughly the same amount of gas as customary generators but this amount of gas must be available three times as fast for the side air bag. Space within the door simultaneously requires a compact size and low height for the side air bag generator.

Gas generator and air bag rest on a carrier plate fixed to the strengt- hened interior door metal. A door panel covers the side air bag module, several rip seams in the door panel provide an opening for release of the side air bag and permit the air bag to expand.

The side air bag is supported in its protection for passengers by a large-area cushion in the pelvis area, ten centimeters thick and made of energy-absorbing foam. A mass of 1.25 kg per side air bag module and 0.3 kg per pelvis cushion is anticipated for the side air bag system in the Porsche study.

The inflated air bag reduces loads on passengers in the areas of the upper body and head during lateral collisions. The cushion in the pelvis area works in similar manner.

Result of the Porsche study is improved passenger projection. Numeric passenger simulations using the latest computer programs, acceleration sled experiments and crash tests suggest an average reduction in passenger loads of around twenty percent.

Porsche's Research and Deveiopment Center, Weissach, is offering the services of production planning as well as small and middle-size production for the first time in 1993, under the heating of Porsche Engineering Services (PES). This expansion of the performance spectrum of PES became possible through restructuring of the pro duction realm at Porsche AG.

Specialists from Zuffenhausen, together with engineers from the Weissach Development Center, now plan and realize innovative solutions for customers from the automobile industry in the newly-established Contract-Productior Cost Center.

The particular performance potential of the Cost Center lies in the production of small and middle-size series to customer contracts. This ran ges from component production through raw body building up to constructior of complete vehicles.

Porsche, together with Audi, presents the latest result of this expanded offering at the IAA in Frankfurt: the Avant RS2 is a repre sentative example of cooperation with another car manufacturer in design and production, with the result that a performance-worthy car, outstanding in both quality and technology could be developed and produced in a minimum time and under economically interesting conditions.

For Porsche, the ideal numbers for such a cooperative venture lie between eight and fifty cars per day, for a technologically demanding car such as the Avant RS2, at up to eight cars per day.

Close cooperation of the Contract-Production Cost Center and the Weissach Research and Development Center - under the wing of Porsche Engineering Services - makes Porsche AG a supplier of complete systems from development of vehicles and components up to their production. Simultaneous engineering is naturally a part of the Porsche performance spectrum.

.jpg)

The demand that engineers consider all relevant environmental requirements during design of a new vehicle has a long tradition at Porsche, For more than ten years a goal of the company, anchored in its basic business principles has been to offer sports cars "with best possible environmental and safety technology".

Porsche demonstrates its latest development success in this realm at the Frankfurt IAA with a cutaway model of the new 911 Carrera. The partially sectioned model indicates through green coloring which elements of the car are already recyclable today.

At the same time, all aluminum components are marked in yellow. These can not only be recycled but, because of lower weight, contribute to reducing resources consumption when operating the vehicle. Aluminum alloys are also used in part, which further increases possible applications of lightweight metals.

It is basic for Porsche sports cars that they be laid out for unusually long life spans. Out of roughly 900,000 Porsche sports cars built to date, more than 600,000 are still in use. Porsche makes a notable contribution to economi- cal use of available resources and energy through the extended life span of its products.

Although Porsche doesn't face the problem of , what to do with old cars", they are working intensively on the subject of parts and components recycling. Since 1988 all newly-developed plastic parts have been codified to permit later, easily-sorted use of the plastics.

To protect resources, carefully treated spare parts are offered which fulfill their functions like new parts. Aluminum, steel and cast parts, batteries, oil, brake fluid, catalytic converters etc have long since been integrated into materials cycles. They are currently working to increase the materials recycling quota considerably from its current level of 75 percent.

All larger plastic parts of the Porsche 911 can be put to top-level use again These include, among others, nose and tail sections, rear and roof spoilers outside mirrors and sill spoilers. In addition, Porsche is working with other manufacturers on various levels of recycling within the PRAVDA framework (an old-car recycling project group of the German automobile industry).

What's more, Porsche AG con- siders all relevant environmental aspects with particular care, in manufacture as well as design. Since production facilities in Stuttgart-Zuffenhausen border on a so-called "general residential area", these production facilities must meet the strictest requirements when it comes to noise emissions and air pollution. Porsche efforts for some time have strived towards the goal of not only meeting legal requirements but reducing environmental pollution well below required limits.

Efforts for enviromentally-compatible production also consider product processes at all the suppliers. For instance, 39 suppliers have produced 250 foamed parts for Porsche vehicles without using CFC since 1991. Suppliers are also urged to deliver in reusable packaging. Porsche is working on requi red environmental standards jointly with its suppliers.

One indication of the quality in Porsche cars are prescribed service and exchange intervals. Engine oil, air and particle filters for the 911 Carrera will only be changed after 20,000 km, for instance. Oil filters as well as spark plugs will be replaced every 40,000 km, the fuel filter and gearbox oil every 80,000 km, while brake fluid needn't be exchanged more often than every three years. Such long change intervals serve to protect the envrionment.

A single environmental protection concept for all Porsche Centers in Germany was prepared in cooperation with Dekra. Porsche was the first car manufacturer in Germany to introduce this concept, in 1992, thus giving dealers the chance of taking a leading and future-oriented position in the field of environmental protection when it comes to car servicing. Integrated waste disposal and recycling is in the preparation stage.

.jpg)

Porsche "Exclusive" is the name of an individual program from the Zuffenhausen sports car manufacturer which permits the already exclusive Porsche sports cars to be matched even more closely to customer wishes. At the IAA in Frankfurt Porsche presents a range of exhibition cars which indicate how desire for the exceptional can be realized in able manner, to the highest quality levels, by experts from headquarters in Stuttgart.

Taking the example of the new 911 Carrera, celebrating its world premiere in Frankfurt, visitors can now have a look at the first model fitted with an Exclusive" program: wide-ranging leather trim in various, matched color shades or the option of eye-catching, valuable wood appliqués for dashboard, center console or door panels. The options for meeting special customers wishes are almost unlimited. This is also demonstrated by exhibition cars from the 968 Coupé, 928 GTS, 911 Turbo 3.6 and new 911 Carrera ranges, showing "Exclusive" fittings.

While Porsche has made individual outfitting of its cars a business principle since the company was founded, naming the additional-wishes program Porsche "Exclusive" only came some ten years ago. Everything a customer might want, from solid gold shift knob to leather colors chosen by the customer personally, even technical car improvements is offered.

Only three basic principles established by Porsche "Exclusive" employees determine possible limits: technical reliability of the car cannot be curtailed, safety compromises will not be accepted and "it must remain a proper Porsche." These basic tenets, combined with the expert knowledge and creativity of "Exclusive" employees, leave such a wealth of variations open that virtually every customer wish could be met up to now.

A further expansion of the Porsche car program is found among Original porsche Accessories. Porsche presents a "Windstop" for the 911 Carrera Cabrio as an important novelty at the IAA. This Windstop consists of a folding slastic frame fitted behind the front seats and covered with a sturdy, perfora ted foil. When the bow is moved to the vertical position, there is a noticeable reduction in passenger-area air turbulence.

The airflow around head and neck areas, which many find annoying, disap pears almost completely. At the same time, a heat cushion is maintained ir the passenger area longer when driving open. This effectively extends the cabrio season. This Windstop also provides a noise level reduction in the pas senger area, Neither holes nor screws are necessary for mounting and seat adjustment is not affected. Porsche will introduce a Windstop for after-sales mounting in the 968 Cabrio shortly as well.

A second important novelty from the Original Accessory program is an alarm unit with remote radio control to supplement the standard Porsche alarm system (968 CS excepted). Code for the remote control is automatically changed with each use and thus impossible for outsiders to break. Ultrasonic interior monitoring as well as electronic drive-away blockage which disconnects starter, ignition circuit and fuel delivery, completes the Porsche anti-theft protection.

A two year warranty applies to all parts from the Porsche Original Accessory program.

Porsche Press kit 1993

.jpg)

Porsche Press kit 1995

Porsche Press kit

Porsche Literature

Our Porsche Cars