.jpg)

1993 968

The number 968 is more than a symbol. Among sports cars in the middle price segment it stands for Porsche identity, for engine output, torque and for anew concept of power transmission in conjunction with economy and high environmental compatibility.

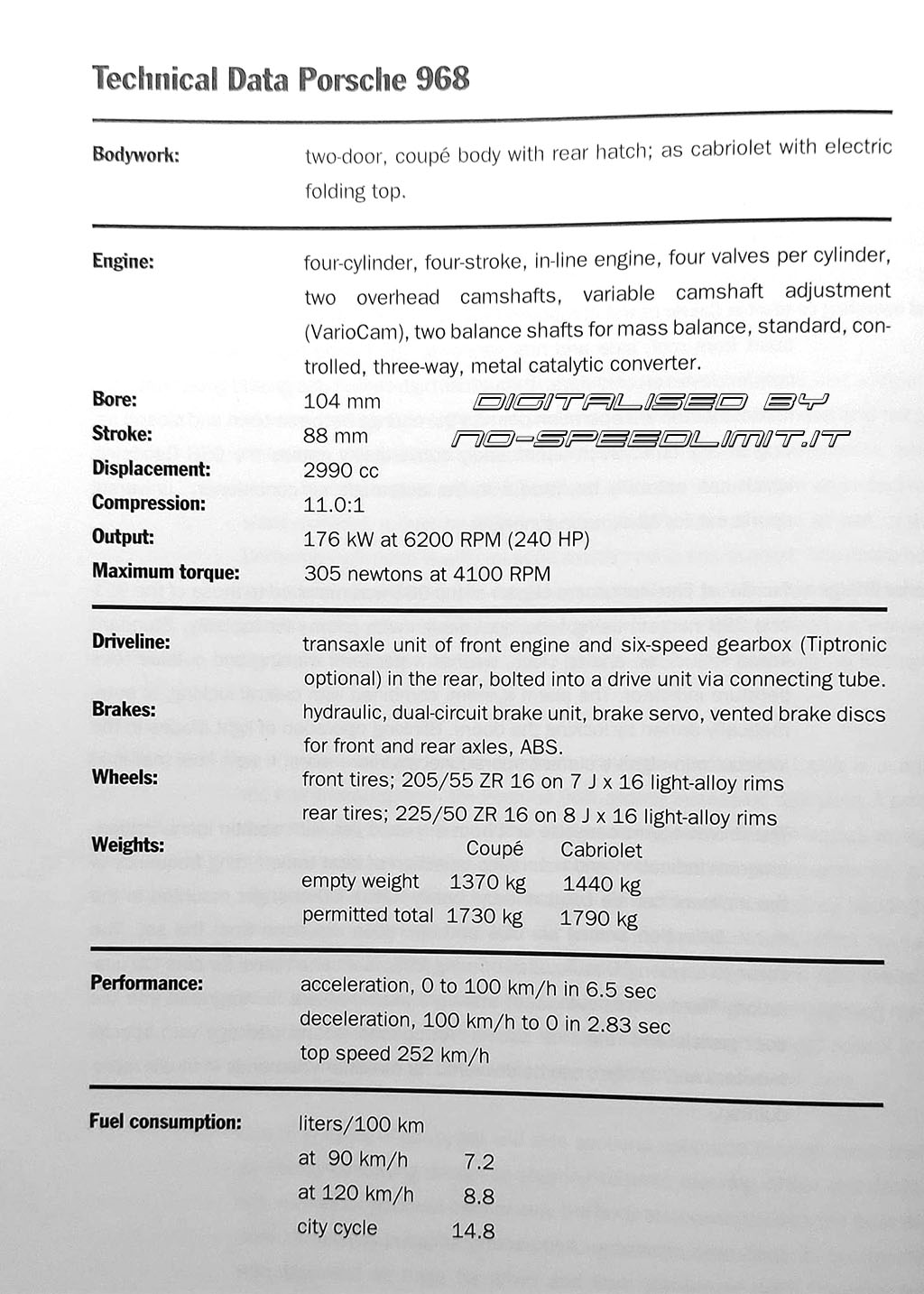

With 176 kW/240 HP and maximum torque of 305 newtons, the four-valve engine with VarioCam intake camshaft control developed by Porsche has the nighest torque figure of any four-cylinder, unblown engine of the 3 liter class in production. A six-speed gearbox or Porsche Tiptronic are options for power transmission, setting standards for sporting and economical use of this performance. The chassis, attuned to direct road-surface contact, the race-tested brake system, standard air bags for driver and front passenger and optimized bodywork structure all indicate the high level of active and passive safety.

.jpg)

The identity of these Zuffenhausen-built Coupé and Cabriolet sports cars iS projected by their body design. The 968 has the appearance of a typical Porsche with large, round headlights, flat, sloping, tapered hood, bumper consequently integrated into the nose and horizontal air-intake slits in the lower nose area. The aerodynamic shape of curving fenders, sill spoilers and side parts (rearview mirrors and door handles in car color), the restrained tail proportions with rear wing in ideal flow position and equally-integrated bumper all produce that balanced overall picture which is characteristic of the function-oriented styling of Porsche sports cars.

The headlights, designed to fold out but always fully in view, are fitted with a reflector system using variable focus which greatly increases light yield. Secondary lights with reflectors produce outstanding high-beam light, integra ted projector fog lights improve lighting to the sides by more than 30 percent and prevent dazzle in fog. The open styling of 16 inch (Cup Design) wheels permits intensive cooling of the race-proven, four-piston, fixed-saddle, vented brakes front and rear with standard ABS, asbestos-free pads and automatic wear monitoring.

The heart of the Porsche 968, its 3 liter four-valve four-cyinder engine stands unchallenged among the best sports car engines in the world. In its characteristic values this power plant is more favorable than most engines of equal displacement but six or eight cylinders Output of 176 kW/240 HP at 6200 RPM and maximum torque of 305 newtons at 4100 RPM give it the highest torque figure of any four-cylinder 3 liter, unblown engine in a production car. Two counter-rotating balance shafts compensate inertia forces and second-order moments and give this four the smoothness of engines with more cylinders. In comparisons of consumption and environmental compatibility it proves one of the best in the world, even when compared to engines of less displacement.

Goals in development of this powerful top engine were favorable specific consumption values and optimum torque production in the lower and middle revolution ranges. A "long" ratio for top gear produces low revs at reduced speeds such as 100 km/h, with very favorable consumption. Thanks to the torque increase, this is achieved without a concurrent loss of elasticity.

These results could only be achieved through a package of measures applied to various areas - such as engine electronics, the intake manifold, valve drive and valves, as well as the exhaust system. In addition, there were weight reductions for individual parts and components.

Precise mixture preparation to favor low exhaust emissions requires pre cise measurement of intake airmass to determine injected fuel amounts in each case. The mechanical air-flow sensor was replaced here by hot-wire measurement of air flow. This produces less pressure loss than a sensor flap and thus contributes to increased performance. An electronic control unit with learning capability of the Bosch Motronic balances individual tolerances and delivers always-precise values to meter sequential fuel injection. Emergency run ning properties are integrated - even in the case of (unlikely) damage to the hot wire, the injection remains functional.

Fresh air flows to the intake distributor of the intake manifold with bypass passage from the front as well as - via the bypass - along the rear. This device, especially adapted to intake features of the four uses pressure waves caused by the intake pattern of the engine and produces high filling efficiency, particularly in the middle and upper revolutlon ranges. This can be clearly seen in the steady, high pattern of the torque curve.

Special layout of intake passages and intake valves as well as intake camshaft control developed by Porsche and called "VarioCam plays a key roll in the performance achieved. It produces a small overlap in the valve lift curves at lower revolutions. This reduces raw emissions of hydrocarbons. Above 1500 RPM it shifts to a favorable position for torque (stronger overlap). Basic timing is again activated at 5500 RPM to achieve maximum output.

VarioCam works through a shifting device in the chain tensioner - controlled by the Motronic - which introduces a delay in intake camshaft drive. This simple, reliable and weight-favorable system is patented by Porsche. Apart from performance and torque, it also has an advantageous effect on exhaust quality. With largest overlap hot exhaust gas pulsates to the intake side, producing an effect similar to exhaust gas recirculation.

High air-flow rate of this engine demands special measures for the exhaust system. These lead to reduction of throttling: pipe diameter was enlarged, a further-developed, metal-core catalytic converter permits reduced exhaust back pressure for a given diameter. Its insulation cover includes a carrying function, a new converter intake throat improves start-up behavior through even coating of the converter. This exhaust system generates low external noise whereas stepping on the throttle in middle and upper revolution ranges produces a sporting sound & for the driver.

Although this is a powerful engine, favorable engine weight could be achieved. By using weight-optimized crank drive, forged rods and light pistons, installation of a torsional vibration damper could be avoided.

Measures applied to the engine meant that good raw exhaust emission values (ahead of the catalytic converter) could be achieved as a contribution to environmental compatibility. Improved filling and compression raised to 11.0:1 contribute to low consumption. General availability of unleaded Super Plus fuel of 98 RON permits the engine of the 968 to be adjusted to this fuel anywhere in the world. Using it brings the best consumption and performance values Thanks to automatic knock regulation, it is posssible to run the engine on unleaded, 95 RON fuel as well - with a loss of maximum output. Fuel provides an important design parameter for a modern sporting engine contributing to favorable consumption and low exhaust emissions.

Porsche was ane of the first manufacturers to move to standard use of the five-speed gearbiox in the 70s. Distributing a speed range exceeding 200 km/h over five gears permitted an optimum ratio for every speed realm, for acceleration on one hand but also for steady driving at low revs on the other. These gear-selection options can be utilized even more strongly with a six-speed gearbox.

Using the performance potential of its 3 liter, four-cylinder engine, the 968 achieves a top speed of around 252 km/h in sixth gear. Set goals of economy in fuel consumption, high engine output for pracical driving and clearly sporting performance were decisive for staging the six fonwvard gears to cover the entire driving range. The gearbox of latest design, developed for this purpose to be mounted ahead of the rear axle in a transaxle layout, uses external-cone synchronization with high shifting comfort. A dual-mass flywheel brings further noise improvement. The relatively small inertia weight of the clutch disk reduces shifting effort.

Since torque of an engine is particularly decisive, along with output, advantages of the six-speed gearbox are obvious for sporting as well as economical driving. The high pulling power of the engine means that sixth gear can also be used at median, or even low, speeds as an especially economical driving ratio. Sixth gear is layed out to the points for top speed. Five gears are available for acceleration and each of them can be taken to better than 6000 revolutions per minute (maximum revs 6700 RPM), while providing optimum acceleration reserves in the partial-load realm as well. This grants a driver a wealth of possibilities for able, aware use of the shift lever.

.jpg)

Porsche Tiptronic as a power-shifted gearbox which offers the option of selecting between automatic and manual shifts, provides an ideal alternative to the six-speed manual gearbox in many ways. Based on a ZF, four-speed automatic gearbox, it fulfills all demands placed on any full automatic with its operating and shifting comfort. Further developed into the Tiptronic system by Porsche it offers clear improvements in its automatic functions when it comes to sporting driving. Beyond that, it also gives a driver the option of determining the actual shift moment, through manual shift capability. Tiptronic is equipped with the Keylock and Shiftlock safety features.

Like the manual gearbox, Tiptronic also offers a choice between various gear ratios at any time. Downshifting to accelerate, when overtaking for instance can be carried out either with the throttle pedal (selector in the automatic blane or through a regular shift (selector in the manual plane"). Due to installation conditions and a lower number of ratios, there is different staging and an altered ratio spread compared to the manual gearbox. Fourth gear is laid out for a top speed of 250 km/h. With Tiptronic the advantages of shif ting without traction interruption and without using a clutch pedal are balanced against the larger selection of gears in the six-speed gearbox. The necessity for constant shifting and clutch use in stop and go traffic - a bother even for drivers who love to shift - disappears.

To expand the automatic functions and permit manual shifts without traction interruption, the purely hydraulic control of the basic transmission is complemented by an electricelectronic unit with self-monitoring function. Microprocessor electronics with adaptive pressure control represent the highest possible level of current technology. The control unit with 8 bit microprocessor and external 32 KB-EPROM memory, produced by Bosch, contains 55 inputs and outputs for communication with system components and the Motronic. It is absolutely fail-safe and insensitive to all influences of driving.

The demands of sporting driving could only be realized with the aid of this highly-developed control, so that the disadvantages of conventional automatic driving no longer have any effect. Tiptronic has five shift maps (SK1 "economy" to SK5 "sport") instead of one or, at best, two. These are activated automatically (adaptive changes of the shift program) to suit driving conditions and driving style without an additional program selector switch. Unwanted overrun upshifts, when the throttle is released before a curve or when cornering, are avoided. Shift comfort is increased through engine input and reduction of shift jerks when downshifting with kick-down. Converter slip is minimized by increasing the driving time component with partially - or fully-mechanical power transmission (in third and fourth gears). Agile start-up could be achieved through optimum converter mapping. Operating mistakes during manual shifts are eliminated by a gearbox control.

The operating control unit with its two shift ranges of automatic planew and "manual planew is located on the central tunnel where its selector lever is easily reached, just like the shift lever of the six-speed gearbox. Transfer from automatic to manual driving is achieved by moving the selector lever sideways to the right from the "D" position; movements between the two drive programs can be done at will. During manual operation upshifts are effected by pressing the lever forwards, downshifts by pulling it to the rear. Electronic monitoring of rev limits prevents overrevving or "killing" the engine. In the automatic mode, adjustment to driving conditions is achieved via data acquisition from throttle pedal movement and lateral accelerations among other things. Rapid throttle depression or release causes late up - and early downshifts, while undesired up - or downshifts are avoided at higher lateral accelerations. Stepping down "slowly" or low lateral accelerations, on the other hand, effect early upshifts and economical driving at lower revolutions. A display in the combination dial tells you what gear the gearbox is using at the moment, for automatic shifts as well.

The two safety systems, Keylock and Shiftlock, prevent faulty reactions when starting or parking. The ignition key can only be inserted or removed and the engine only started when the selector lever is in its park or "P" position (Keylock).

Shiftlock permits selection of driving ranges "R" or "D" from park position "P" or neutral "N", but only when a driver also has one foot on the brake pedal. Unlike other Shiftlock systems, shift lockout with Tiptronic can also be released, when the brake pedal is operated, if the driver applies previous pressure to the selector lever.

With its sporting and direct basic chassis setup, the Porsche 968 equals 911 models. This means the chassis not only matches the exceptional per formance but also provides a high level of driving pleasure and a safe feeling for handling and road-surface contact. The MacPherson front axle is laid out to meet demands of driving stability as well as braking behavior in conjunction with ABS, In harmony with precise servo steering operation, this achieves an agile, safe steering response, Wheel hubs and axle struts are made of high quality aluminum, the stabilizer is made of hollow, seamless, drawn stee tubing.The semi-trailing arm rear axle with elasto-kinematic layout of the sub-frame contributes to unproblematic, easily-controlled cornering manners of a Porsche 968 as well as high possible lateral accelerations. Twin-tube gas-pressure shock absorbers, in conjunction with responsive yet intentic nally stiff front springing and sturdily-dimensioned rear-axle torsion bars, pro vide a sporting overall layout which simultaneously offers good touring comfort. A clearly sporting chassis layout with vehicle height adjustment via the spring plates, shock absorbers adjustable for rebound and modified springs and stabilizers, is an option. This sports package comes with 17 inch wheels and even larger brake dimensions, thanks to space available within the larger rims.

The ABS brake unit, in conjunction with properly attuned chas sis, brings a true safety plus, particularly during panic braking. Even with very different grip conditions left and right, the yaw moment is reduced and the car stabilized. Four-piston, fixed-saddle brakes with vented brake discs for the ront and rear axles, proven in racing and on the 911, offer total equivalence to the high performance of a Porsche 968 with their efficiency and durability lerodynamically refined cooling of the front brakes, heavily loaded under ful raking, contributes to low brake fluid temperatures, as does the good heat conductivity of aluminum housings and internal cooling of the cast iron brake discs. Low brake weight reduces unsprung masses and thus assures fine spring reaction. Optimum surface protection and rust-free add-on components ensure long life for the brake system. Asbestos-free brake pads with properties further developed through racing experience, are notable for their higr coefficient of friction stability. Wear of each pad is monitored individually by a sensor.

The typically-Porsche, functionally-oriented design is as evident in the bodywork surface as beneath the skin. With an air resistance index (Cd x F) of 0.64 the 968 Coupé ranks worldwide among production cars with very low overall air resistance. A very low rear axle lift value of only CRI = 0.06 demonstrates that the low Cd value (coefficient of drag) of 0.34 was not achieved at the cost of safety.

With convincing engine output and road performance in the sporting realm. Cooling of engine, components and brakes presents high demands. The Concept for cool-air intakes and flow direction management ensures cooling for all operating conditions on one hand, while the share of internal flow in overall resistance is kept low at a very favorable value of Cd = 0,016 for this performance class on the other. Cool air routing to the front brakes is handled by passages in the lower nose and a combination of directional spoiler and baffle aimed directly at the front brake discs

Great emphasis was placed on protection against stone chips and avoidance of body damage from light bumps or contacts. Design of the nose and tail portions with integrated impact dampers, respectively impact elements, which retum to their original shape following a collision, sheathing in an impact-resistant material, robust air grls in the tail and PU side sills are all part of this Uniformly nigh paint quality must be mentioned in this context. The entire body is made of sheet steel, hot-dip galvanized on both sides so that Porsche can provide a ten-year warranty against rust perforation with a three-year warranty for paint. The entire car is covered by a two-year warranty with no kilometer limit.

A reflector system with variable focus is used in the round headlights of the Porsche 968, greatly increasing light yield. A safety release in the folding mechanism avoids damage from foreign bodies wedged into the wells. Headlights plus console form a complete pre-assembly unit which can be easily fitted or exchanged. Reflectors of the auxiliary headlights and projector fog lights are laid out to provide optimum light effect for each specific purpose. The driver has far-reaching, bright high-beam light available when the road is clear, dazzling is avoided in fog and high lateral lighting achie ved. Rear lights of solid red outside color radiate through special optical units and color filters to produce white reversing light and yellow blinkers.

Due to shaping of nose, tail and side sections optimized through crash tests, an energy-absorbing design of steering column, steering wheel and dashbo ard, as well as a robust interior cell, the body structure provides the best accident protection possible. Three-point, automatic seat belts in combination with standard air bags for driver and front passenger (968 CS excepted), ensure the best possible protection level known today in a 968, in many different kinds of accidents.

16 inch wheels in Cup design serve brake cooling with their open form as well as providing an identifying feature for the new Porsche generation. Tire sizes front and rear are traditionally differentiated: the standard car mounts 205/55 ZR 16 tires in front, the wider 225/50 ZR 16 size in back. Wheels of 17 inches and a new Cup design are a special option, mounting 225/45 ZR 17 and 255/40 ZR 17 tires front and rear.

Coupé and Cabriolet are identical in design and fittings, apart from roof, side and rear windows. The Cabrio top provides full driving comfort, even on cold days, through its high-caliber design and good heat insulation. Electric top operation permits the change between open and closed driving at any time. Such user-friendly convertibility makes the 968 Cabriolet, which can naturally be fitted with the automatic air conditioner, universal sports car for all climatic zones.

The instrument cluster of the 968 was matched to those of the 911 and 928 ranges, using functional design with priority for legibility. Standard items include an analog clock, washer water level warning and outside temperature indicator. The alarm system, combined with central locking, is automatically armed by locking the doors. Blinking operation of light diodes in the lock buttons signals current operational status .

The Bremen radio-cassette unit from the radio list, with station identification program indication and automatic selection of best transmitting frequency of the moment can be combined optionally with a CD changer mounted in the trunk. Selection among six CDs and operation are done from the set. The Porsche London CD radio, also offering RDS, is an alternative for pure CD operation. The two-way system of standard loudspeakers is integrated into the door panels and rear side panels. An optional sound package with special tweeters and woofers can be delivered for maximum demands in music reproduction.

.jpg)

1993 968

.jpg)

1995 968

Porsche Press kit

Porsche Literature

Our Porsche Cars