.jpg)

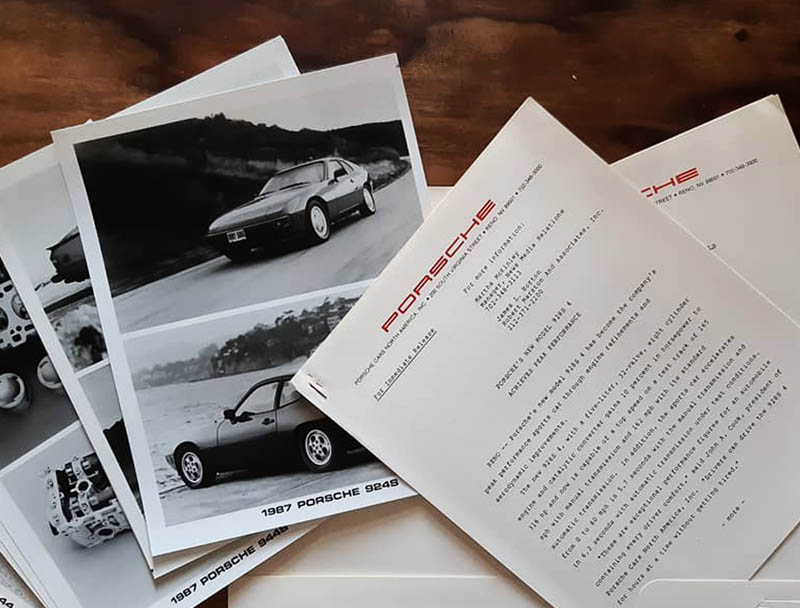

Porsche Experimental Prototype (PEP)

At the 1981 IAA in Frankfurt, Porsche presented the "Porsche 960" vehicle study for the first time. This sports car, which looks like the Porsche 928, contains a number of new and further developments. In particular, they result in lower fuel consumption and even more safety and comfort and could be introduced into series production in the not too distant future.

.jpg)

The saving technology begins with the Thermodynamically Optimized Porsche engine (TOP engine). Its special features include an optimal compression ratio (12.5 : 1), pronounced turbulence of the fuel-air mixture in the combustion chamber and optimization of the ignition timing using digital engine electronics. and air ratio map

In order to minimize energy losses during power transmission, Porsche chose a powershift 5-speed transmission with a dual clutch. During the gear shift, 2 gears are engaged, but only one gear is engaged. The actual gear change is carried out by simultaneously disengaging one gear and engaging the next. The driver's foot can remain "on the gas" during this process. In conjunction with electronic control of this transmission, it can be developed into a fully automatic system, particularly with a design based on economy/sport aspects.

The advantages of this transmission are not least its good efficiency and low weight compared to a 4-speed torque converter transmission.

The extensive use of lightweight materials reduced the total weight of the car to 1090 kg.

The front end, doors, front fenders and bonnet are made of aluminium. The weight advantage achieved in individual components compared to steel is up to 50 percent. Four to five times the material costs per kilogram of aluminium compared to steel are offset by high value retention due to lower corrosion sensitivity and, due to the design, high repairability: at impact speeds of up to 40 kilometres per hour, repairs can be limited to replacing the front duble struts.

For the first time, Porsche also used new high-strength steels (HSLA) in the "960" study, including parts of the side structure, the rear side panels, the vehicle roof and the rear lid.

Sheets made of HSLA steels have a yield strength that is up to 100% higher than that of standard body steels, while having a formability that is almost comparable to that of conventional body steels. This makes it possible to save weight on parts whose dimensions are primarily influenced by strength.

Since the energy absorption during plastic deformation of high-strength steels also increases compared to body steel, the weight of energy-absorbing structures can be reduced. The realized weight advantage for individual components is 43%.

The bumper material is also completely new. It is wound, glass fiber reinforced plastic, which can absorb two to three times more energy than steel or aluminum tubes of the same weight. The winding technology enables targeted lightweight construction because the reinforcing fibers are arranged in the direction of stress. With this component alone, Porsche has saved 4.8 kg in weight compared to today's series technology. And the transaxle central tube has a weight reduction of 32 percent: instead of steel, it is made of glass fiber reinforced plastic in the "Porsche 960" study.

.jpg)

In order to keep the consequences of accidents as low as possible, Porsche has invested considerable development effort in the "960" study to increase passive safety - for the benefit of the occupants on the one hand, but also to a large extent for the benefit of affected pedestrians and other vehicles. In frontal collisions, energy absorption has been improved by the use of optimized double-tube longitudinal members on both sides. The height of the lower double tube corresponds to the sill height of 42 European vehicles. This benefits the protection of collision partners when they hit their side of the vehicle. Without increasing weight, Porsche has also increased the wall impact speed from 48 to 59 km/h. With these and other measures, Porsche expects a ten percent reduction in the number of injuries in frontal collisions alone.

Porsche expects the number of injuries to be reduced by 20 to 30 percent even in side collisions. The door clamps, door reinforcements and reinforcement of the vehicle floor in the transverse direction should contribute to this.

The sweeping V-shaped front structure, the more than two-meter gap between the road and the lower windshield frame as well as energy-absorbing integrated bumpers, hood and fenders ensure optimized pedestrian protection. These design measures should reduce the number of pedestrian injuries by 20 percent.

Direct occupant protection is provided by vehicle seats with a new integrated belt system, belt tensioners and low-stretch belt strap with optimal belt routing in all seating positions. With this system, Porsche has achieved a reduction in head load of 30 to 50 percent. Light but highly effective interior upholstery elements ensure that head impacts remain below the load limits even at impact speeds of up to 25 km/h.

A central information and warning system with a microprocessor-controlled display system using LCD technology is designed to detect any defects, errors and necessary information that occurs, process them logically, evaluate them and display them to the driver in an appropriate form.

The display itself is shown on a display in the driver's primary field of vision, which enables the display of alphanumeric character strings.

The tire pressure control system, which has already been tested in races and was jointly developed by Bosch and Porsche, also informs the driver about critical deviations from the target pressure. Studies have shown that over 50% of all vehicles are driven with tire pressure that is too low. This results in higher rolling resistance and therefore fuel consumption and can lead to the sudden destruction of the tire, particularly at high speeds.

Comfort and safety often go hand in hand in cars. This is also the case in the "Porsche 960" study. The seats have hydropneumatic suspension, which reduces the average vibration load on the occupants by half. The damping can be adjusted to the occupant's weight, driving speed and road conditions. These seats also allow an even firmer and therefore safer chassis design without compromising comfort.

To protect the vehicle interior from overheating due to sunlight, Porsche has applied opaque strips on the rear window at defined intervals on the outside and inside, which reduce the area of sunlight that is reflected by 60 percent when the sun is vertical. However, the transparency of the rear window only decreases by 30 percent.

Even with the good safety of previously known child seats, disadvantages could not be eliminated: On the one hand, the child could only participate in the environment to a limited extent. On the other hand, the driver or front passenger could not monitor the child without affecting their seat adjustment.

Porsche has therefore modified a tried and tested seat system for installation in Porsche sports cars and improved comfort for children and parents: The seat is placed between the rear seats on the transaxle tunnel and secured in the vehicle by 3 fastening points and the seat base adapted to the center tunnel.

.jpg)

Porsche Experimental Prototype (PEP)

.jpg)

Porsche FLA - Forschungsprojekt Langzeit-Auto

Porsche Press kit

Porsche Literature

Our Porsche Cars